Wragg Well Drilling & Pump Service provides an all-inclusive, 24 hour pump service.

As a member of the Gould’s Professional Dealers Association (GPDA), our pump technicians have the necessary expertise.

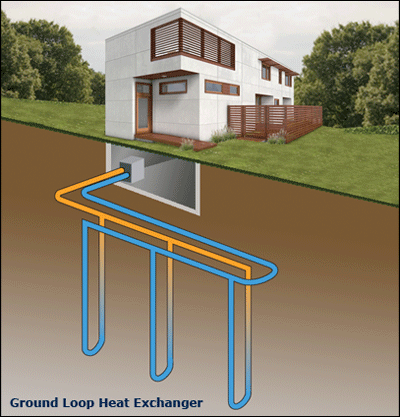

Most simply, a Ground Source Heat Pump is an electrically powered system that uses the stored energy of the earth, to heat and/or cool a space.

In an average year, the earth absorbs roughly 47% of the energy delivered to its surface by the sun. This is 500 times more energy than we use in a given year. Geothermal Systems tap into this endless source of renewable energy by exploiting the fact that the absorption of the sun’s rays by the earth creates a near constant deep earth temperature throughout the year. Geothermal energy is clean, renewable, and sustainable.

In other words, when outside air temperatures reach 100˚F or even when they fall to -25˚F, the temperature of the earth just a few feet below the surface stays constant. While deep-earth temperatures vary depending on soil composition, region, and yearly average air temperature, it is always cooler than the air temperature on your hottest days and warmer than the outside air temperature on your coldest days.

Driven by the basic vapor-compression refrigeration cycle, Geothermal units extract heat from the earth during the winter months and reject heat to the earth during the summer months through a ground heat exchange. An air source heating or cooling unit (air-source heat pump, ASHP) uses the outside air as its source when heating or cooling a space. Because of this fact, an air-source heat pump has to use a lot more energy to bring that air to the desired temperature. Think about it this way, boiling an ice-cube will take more heat and more time than boiling tap water. This is where the advantage of the GSHP system resides, using the near constant moderate temperatures below the earth’s surface rather than using the extreme outdoor air temperatures as a heat source/sink.

Both ground heat exchange systems are proven, effective, and efficient. Here are some factors that should be considered when selecting the best Ground Heat Exchanger for your home or business geothermal system

1.) Availability of Land/Lot Size – Heating & Cooling Loads will determine the size and amount of underground piping required to support your needs. Generally, larger loads or demands require a more substantial amount of ground heat exchanger.

2.) Geology and soil conditions – Certain types of soils and rock formations conduct and transfer heat more effectively than others. Consider formation thermal conductivity testing for vertical systems requiring 25 tons or greater. Determining formation thermal conductivity and diffusivity values can help design a better, more effective groundloop. In the northeast, vertical systems are particularly well suited for ground heat exchangers because of the presence of hard rock. There are always deviations from this tendency. Contact a member of Wragg Well Drilling to discuss the geological formations of your area to help determine the best suited system for your property.

3.) Water Quality/Availability (Open-Loop Systems) – Many water well owners assume that they can turn their existing water wells into ground heat exchangers. This is possible in some applications, but more often than not, this is not recommended or practical. The two serve two very different functions even though structurally they are almost identical. Consider the presence of metals, minerals, pH, and hardness and water yield before determining that an open loop system is best suited for your geothermal system.

4.) State Codes & Regulations – In general, health departments look at closed loop systems more favorably because no groundwater is being extracted from the earth. Because of this, placement of vertical closed loop bores are given more latitude.

(For the State of CT recommendations for regulation of geothermal wells,

click here.)

5.) Future Development of Property – Because the ground heat exchanger is completely buried beneath grade and invisible to the eye upon completion, be aware of future plans for land development. For example, consider pools, patios, and additions.

There are advantages to both ground heat exchanger types; closed and open loop systems. Contact a professional heating and cooling contractor or an IGSHPA accredited Well Drilling to discuss which system is right for you

Here are some useful links for further consideration: